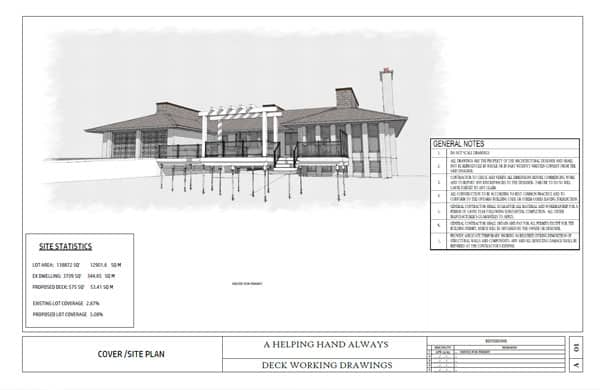

3D Deck Design in Barrie

Let’s talk about 3D deck designs. There are quite a few companies doing designs using everything from stock to specialty software to professional rendering tools. Results may vary. We are specialists in carpentry details and 3D modeling of homes and decks in particular.

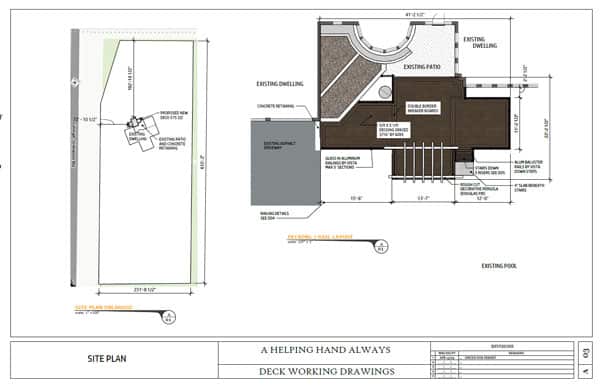

Here’s an example of a design concept and permit plans for a large deck in Barrie, Ontario. This one is “Accessible” and involved plenty of custom detailing since the builder would have to cut, preserve partially, and remove the rest of a partially rotted elevated concrete slab.

The patio was supported by masonry walls, and the brick had been damaged by moisture. In our area, masonry that gets wet deteriorates from frost.

Project at a Glance

Location: Midhurst (Springwater Township), Ontario

Client: A Helping Hand Always Group Home

Challenge: Replace decomposing elevated concrete patio with rotting brick masonry

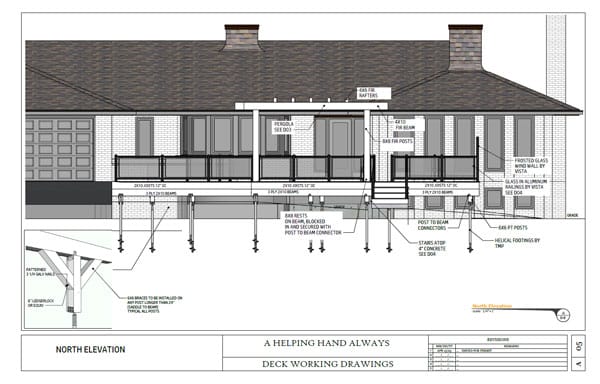

Solution: Accessible deck on helical pile foundation with glass railings and Douglas fir pergola

Special Features: Wheelchair accessible, autism-friendly design, landscape lighting

Result: Zero damage when large tree branch fell during ice storm (ultimate torture test)

Key Innovations:

- 100-year helical pile foundation system

- Salvaged and reinforced 50-year-old concrete slab (originally held together with vintage tractor parts!)

- Glass railings maintaining light to basement windows

- Frosted glass wind walls providing privacy and weather protection

- 3-ply 2×10 beams + 2×10 joists @ 12″ o.c. (50% stronger than code)

- Premium Azek solid PVC decking with Cortex hidden fasteners

Timeline: 40 years of design-build experience meets modern engineering challenges

The Full Story: When a Deteriorating Patio Becomes a Life-Enhancing Deck

Let’s talk about professional 3D deck design in Barrie – not the generic software mockups you’ll find elsewhere, but true architectural design that solves real structural problems while creating beautiful, functional outdoor spaces.

This project in Midhurst (Springwater Township, near Barrie) transformed a decomposing elevated concrete patio into a spectacular accessible deck for a group home serving young adults with autism. What started as a straightforward deck replacement became a comprehensive structural rescue mission – the kind of challenge that separates real design-build expertise from theoretical drawings.

For over 40 years, we’ve specialized in carpentry details and 3D modeling of outdoor structures throughout the Barrie, Springwater, and Simcoe County region. We don’t just create pretty pictures – we design solutions that builders can actually construct, that pass building department scrutiny, and that last for generations.

The Problem: A Patio Decomposing in Real Time

When “A Helping Hand Always” – a company operating five group homes in the Barrie area – contacted us about their property in Midhurst, the situation was urgent. The existing elevated concrete patio was failing on multiple levels:

Masonry Failure from Ground to Grade

The original construction used brick masonry at ground level and for raised planters. In our Ontario climate, this was a ticking time bomb. The brick had rotted from moisture infiltration combined with brutal freeze-thaw cycles. This wasn’t just cosmetic damage – it was structural deterioration threatening the entire assembly.

The problem compounded at the planter boxes, where water leaked from compromised eavestroughs directly into the masonry. Year after year of freeze-thaw cycles had taken their toll. What looked solid was quietly falling apart.

Below-Grade Windows and Compromised Garden Walls

The original designers had constructed planter boxes to create channels for operable basement windows beneath grade – a clever concept that had become a maintenance nightmare. Add to this a large tree that had compromised an 8-foot-deep garden wall near the house, and we had a comprehensive structural crisis.

The Hidden Challenge: What Lurked Inside the Slab

We knew the concrete slab itself was questionable. What we didn’t know – because I don’t have x-ray glasses yet – was what we’d find during demolition.

Turns out, the original builders had reinforced this patio with… tractor parts. Not modern rebar. Actual vintage tractor chassis components, frames, leaf springs, and galvanized plumbing pipe. The demolition became a grinding, painstaking process. But I’ll give credit where it’s due: that improvised reinforcement had kept the slab remarkably intact for over 50 years with barely a crack.

Still, a patio held together with farm equipment isn’t something you can build a modern accessible deck on top of.

The Design Phase: 3D Photorealistic Deck Renderings

Before any demolition began, we needed a comprehensive plan. This is where professional 3D deck design separates from basic layout drawings.

Why 3D Renderings Matter for Complex Projects

When you’re dealing with:

- Structural repairs to existing masonry

- Integration with a compromised concrete slab

- Accessibility requirements for wheelchair users

- Building code compliance in Springwater Township

- Client visualization for a group home board of directors

- Contractor coordination for multiple trades

…you can’t work from sketches on napkins. You need detailed, photorealistic 3D renderings that show exactly what you’re building.

Our 3D deck design process for this Barrie-area project included:

Structural Assessment Renderings: We modeled the existing conditions, including the failing masonry and concrete slab, to help everyone understand what we were dealing with.

Design Development Renderings: Multiple iterations showing how the new deck would integrate with the repaired structure, accommodate basement windows, and create accessible pathways.

Material Specification Renderings: Detailed views showing the Azek solid PVC decking, glass railings, Douglas fir pergola, and frosted glass privacy screens – so clients could see exactly how finishes would look.

Lighting Design Renderings: We created nighttime renderings showing how exterior and deck lighting would perform after sunset, allowing us to optimize fixture placement before installation.

Construction Detail Renderings: 3D models of critical connection points, helical pile placements, and framing details that contractors could reference during construction.

Working with Springwater Building Department

Here’s where having 40 years of design-build experience in the Barrie region matters. The Springwater building department worked collaboratively with us once we communicated what we were actually dealing with.

The original plans had to adapt when we discovered the extent of the structural issues. Building inspectors appreciate designers who understand real-world construction challenges and can pivot intelligently when conditions change. Our 3D renderings helped communicate these changes clearly.

As I told the inspector: “I don’t have x-ray glasses yet – if I did, I could have predicted all those tractor parts holding the slab together.” He appreciated the humor and the honesty. This is the kind of relationship you build over decades of quality work in a region.

The Structural Solution: Engineering for the Next Century

Helical Pile Foundation System

We weren’t going to build a beautiful accessible deck on a questionable foundation. This needed to last.

The entire deck structure sits on helical piles – engineered foundation systems that provide 100-year performance. These aren’t your grandfather’s concrete piers that heave and settle. Helical piles are screwed deep into stable soil, providing permanent, frost-proof support.

But we went further. We also supported the salvaged portions of the concrete slab itself with P3 helical piles topped with welded plates. Now the deck and the remaining slab share the load distribution. The patio that was poised to collapse became a permanent, stable platform.

This is the kind of engineering that makes a deck last generations instead of decades.

Masonry Repair Before Deck Construction

All compromised masonry had to be professionally repaired before any decking work could begin. We coordinated with masonry contractors to:

- Remove and replace deteriorated brick at ground level

- Rebuild planter boxes with proper waterproofing

- Address moisture infiltration from eavestroughs

- Stabilize the 8-foot garden wall compromised by tree roots

- Ensure proper drainage away from the foundation

This wasn’t cutting corners to save money – this was doing it right so the entire assembly would last.

Cutting and Adapting the Concrete Slab

We carefully cut away compromised portions of the concrete patio, creating clean edges for the deck transition. The design had anticipated this – we’d modeled the integration before demolition began. But flexibility in execution is crucial when dealing with 50-year-old structures full of surprises.

The final result? A seamless transition between salvaged concrete (now properly supported) and new composite decking.

Premium Materials and Construction Details

Heavy-Duty Framing System

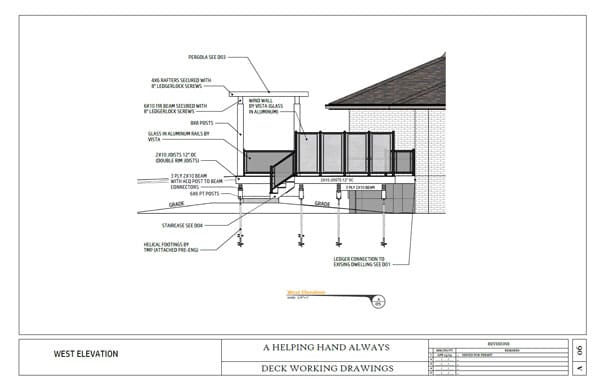

This deck was built to last and built to code-plus standards:

Beams: 3-ply 2×10 construction (far exceeding standard requirements)

Joists: 2×10 lumber spaced at 12 inches on center – that’s 50% stronger than code minimum

Moisture Protection: Every framing member has sealed end cuts and joist flashing tape applied everywhere. This is how you prevent rot and ensure 30+ year performance from the structure behind the decking.

Azek Solid PVC Decking

For the decking surface, we specified Azek solid PVC – premium composite decking that will outlast the clients and probably the next generation of clients.

Installation used the Cortex hidden fastening system combined with edge clips for a clean, professional appearance with no visible screws. This isn’t just aesthetic – it’s about water management and long-term performance.

Glass Railings for Light and View

One of the design challenges was maintaining natural light to basement windows while creating a safe, code-compliant deck. The solution: glass guard railings.

These transparent railings allow ambient light to reach the below-grade windows while meeting Ontario Building Code requirements for fall protection. The basement spaces stay bright and connected to the outdoors.

The deck is stepped out approximately 3 feet from the house, creating a generous landing area while ensuring basement windows remain fully functional.

Architectural Features: Pergola and Privacy Screens

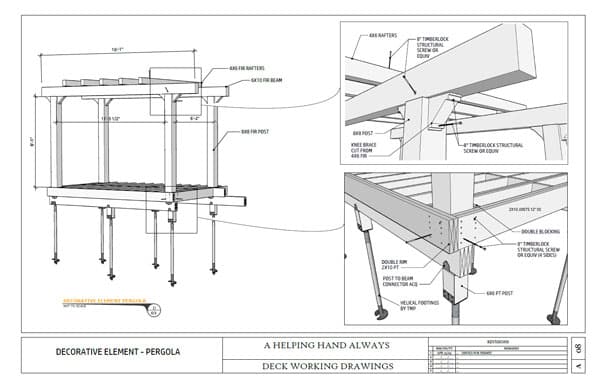

Rough Cut Douglas Fir Pergola

Midhurst sits on elevated terrain where wind is a significant factor. We designed a substantial pergola in rough-cut Douglas fir with diagonal bracing engineered to resist the fairly dramatic wind loads common on this hillside location.

This isn’t decorative trim – it’s structural architecture designed for real-world conditions. The rough-cut Douglas fir provides both strength and character, creating defined outdoor rooms within the deck space.

Frosted Glass Privacy Screens as Wind Walls

The deck faces the road, creating both privacy concerns and wind exposure. Our solution: frosted glass privacy screens that serve double duty.

These panels provide visual privacy from the street while creating sheltered sitting areas protected from prevailing winds. The frosted treatment maintains light transmission while obscuring views – perfect for a group home where residents deserve dignity and comfort.

The glass panels are structurally integrated into the deck framing, engineered to resist the wind loads we calculated for this exposed location.

Accessibility Features: Universal Design

This deck serves young adults with autism at a group home. Accessibility wasn’t an afterthought – it was central to the entire design.

Wheelchair-Accessible Transitions

We poured a concrete threshold between the driveway and deck, creating a smooth, ADA-compliant transition. No steps, no bumps – just seamless access for wheelchairs, walkers, or anyone with mobility challenges.

The deck’s generous width and open layout provide plenty of maneuvering room for wheelchairs and groups gathering together.

Spacious, Open Design for Multiple Users

Group homes need space for multiple residents to enjoy fresh air simultaneously without feeling crowded. This deck provides generous square footage with defined zones:

- Covered pergola areas for shade

- Open sun exposure zones

- Sheltered sitting areas protected by glass screens

- Multiple access points for easy circulation

Thoughtful Details for Autism-Friendly Design

Working with “A Helping Hand Always,” we incorporated features that support young adults with autism:

- Clear sightlines (no hidden corners that can create anxiety)

- Defined spaces that provide structure without confinement

- Durable materials that won’t show excessive wear from stimming behaviors

- Multiple seating options for different comfort preferences

- Visual privacy from street traffic while maintaining openness

Landscape Lighting Design

A deck should be as beautiful at night as during the day. We created a comprehensive landscape lighting design showing clients exactly what their completed deck would look like after sunset.

Strategic Fixture Placement

Our nighttime 3D renderings allowed us to optimize lighting placement before any electrical work began:

- Pathway lighting for safe navigation

- Accent lighting highlighting the Douglas fir pergola

- Ambient lighting creating comfortable gathering areas

- Task lighting for functional zones

- Safety lighting at transitions and stairs

Creating Atmosphere and Safety

Deck lighting isn’t just about visibility – it’s about creating inviting outdoor spaces that extend the home’s living area into evening hours. Our lighting design balanced:

- Safety requirements (especially crucial for a group home)

- Aesthetic atmosphere (warm, welcoming light quality)

- Energy efficiency (LED fixtures throughout)

- Maintenance access (easily replaceable bulbs)

The completed installation brings the deck to life at night, creating a magical outdoor space for residents to enjoy summer evenings.

The Ultimate Torture Test: Ice Storm Survival

The winter after completion, Barrie experienced a significant ice storm. A large branch fell directly onto this deck during the storm.

Damage assessment: None.

Zero. Not a crack, not a loose board, not a bent railing. The heavy-duty framing, engineered foundations, and quality materials did exactly what they were designed to do.

I would call that the ultimate torture test. When Mother Nature throws her worst at your work and it doesn’t even flinch, you know you built something right.

Our Relationship with “A Helping Hand Always”

This wasn’t our first project with “A Helping Hand Always” – and it won’t be our last.

About 10 years earlier, we designed their first deck for Junior, who built it himself using our plans. That relationship has evolved to the point where we’ve become their dedicated architectural designers for all five of their group homes in the Barrie area.

This is what happens when you do quality work: clients come back. And back. And back.

They trust us because we:

- Understand their unique accessibility needs

- Design for durability in institutional settings

- Work within budget constraints

- Solve problems instead of creating them

- Deliver designs that actually get built successfully

We’re not just vendors – we’re long-term partners in their mission to provide quality living environments for young adults with special needs.

Why This Project Showcases Professional 3D Deck Design

Let’s be clear: there are plenty of companies offering “3D deck design” services. They’ll use stock software to create generic visualizations that look pretty but don’t solve real problems.

This project demonstrates what professional architectural design actually means:

We’re Specialists in 3D Modeling and Carpentry Details

Forty years of hands-on building experience informs every line we draw. We don’t just know how to make something look good in rendering software – we know how to build it, how it will perform over time, and what details will prevent problems decades later.

We Design for Real-World Conditions

- Structural problems? We engineer solutions.

- Building code requirements? We exceed them.

- Challenging site conditions? We adapt.

- Surprises during demolition? We pivot intelligently.

We Create Construction-Ready Documentation

Our 3D renderings aren’t just sales tools – they’re construction documents. Contractors can build directly from our detailed models. Building departments can review and approve our drawings. Clients can see exactly what they’re getting.

We Understand Local Building Codes

We’ve been working with Springwater, Barrie, and Simcoe County building departments for decades. We know what inspectors expect, what details they’ll scrutinize, and how to design for smooth approval.

We Stand Behind Our Work

When that ice storm branch hit this deck and caused zero damage, it validated every decision we made during design. Heavy framing, helical piles, quality materials, proper construction details – it all matters.

Our 3D Deck Design Process in Barrie and Simcoe County

If you’re considering a deck project in Barrie, Springwater, Tiny Township, or anywhere in Simcoe County, here’s what working with us looks like:

Phase 1: Site Assessment and Consultation

We meet at your property to:

- Assess existing conditions

- Identify structural concerns

- Understand your vision and needs

- Discuss budget realities

- Explain what’s possible (and what’s not)

Phase 2: Preliminary 3D Renderings

We create initial 3D visualizations showing:

- Layout options

- Material selections

- Integration with your home

- Accessibility features

- Approximate costs

These aren’t final designs – they’re conversation starters that help refine your vision.

Phase 3: Design Development

Based on your feedback, we develop detailed 3D renderings including:

- Precise measurements and specifications

- Material specifications

- Lighting design (day and night views)

- Multiple viewing angles

- Structural details

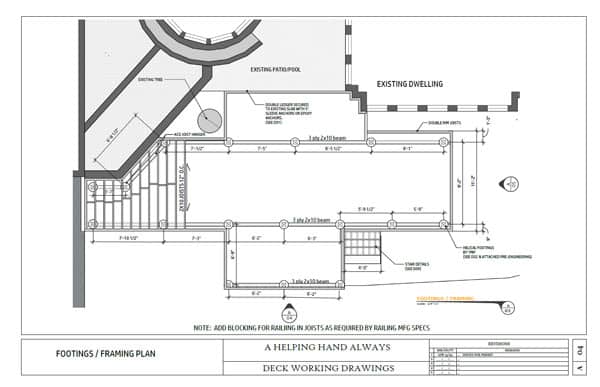

Phase 4: Construction Documentation

We produce complete permit-ready drawings:

- Site plans

- Foundation details (including helical pile specifications if needed)

- Framing plans with every beam, joist, and connection

- Railing and stair details

- Electrical plans for lighting

- Material specifications contractors can price from

Phase 5: Building Permit Support

We work with your local building department to:

- Answer technical questions

- Provide additional details if requested

- Make revisions for code compliance

- Ensure smooth approval

Phase 6: Construction Support (Optional)

If we’re building your deck, you work with the same team that designed it – no communication gaps, no surprises. If another contractor is building, we’re available to answer questions and ensure design intent is maintained.

Details That Make Our Decks Last 30+ Years

Moisture Management is Everything

Wood rots. Even pressure-treated lumber will eventually deteriorate if exposed to constant moisture. Our standard detailing prevents this:

Sealed End Cuts: Every cut end of every framing member is sealed before installation

Joist Flashing Tape: Applied to all horizontal surfaces where water can sit

Proper Drainage: Designed into the structure, not an afterthought

Material Selection: We specify materials appropriate for your specific conditions

Engineered for Local Conditions

Barrie and Simcoe County experience:

- Heavy snow loads in winter

- Freeze-thaw cycles that destroy inadequate construction

- Wind exposure on elevated or lakefront properties

- Soil conditions that require proper foundation engineering

We design for these realities, not generic conditions from a textbook.

Oversized Framing for Long-Term Performance

Code minimums are exactly that – minimums. We typically design decks with:

- Heavier beams than required

- Closer joist spacing than required

- Better fasteners than required

- More robust connections than required

Why? Because a deck that meets code minimum standards today will be sagging and bouncing in 15 years. A deck built to our standards will still be solid in 50 years.

Why Photorealistic 3D Renderings Matter

Let’s address the elephant in the room: why pay for detailed 3D renderings when simple drawings or basic computer mockups cost less?

Visualize Before You Commit

A deck is a major investment – often $30,000 to $100,000+ for complex projects like the Midhurst group home. Making changes on paper costs nothing. Making changes during construction costs thousands.

Our photorealistic renderings let you:

- See exactly what materials will look like together

- Understand how the deck relates to your house

- Evaluate different layout options side by side

- Make informed decisions about upgrades or modifications

- Feel confident you’re getting what you want

Communicate Clearly with Contractors

Ever play telephone as a kid? By the time a message passes through several people, it’s completely different.

Without clear visualizations:

- You describe your vision to us

- We translate it to drawings

- Contractors interpret those drawings

- What gets built may not match your vision

With detailed 3D renderings:

- Everyone sees exactly the same thing

- Contractors bid on what you actually want

- No surprises during construction

- Fewer change orders and disputes

Streamline Building Department Approval

Building inspectors deal with poorly documented projects every day. When they receive professional 3D renderings with complete specifications, it:

- Demonstrates competence and attention to detail

- Makes their job easier (they can see what you’re proposing)

- Speeds up the approval process

- Reduces requests for additional information

Calculate Accurate Costs

Generic deck designs leave huge pricing variables. Contractors have to pad their bids to account for unknowns. Detailed renderings with material specifications let contractors provide:

- Accurate material takeoffs

- Competitive pricing (they know exactly what they’re bidding)

- Fewer contingencies and allowances

- Better value for your investment

Serving Barrie, Springwater, and Simcoe County

We’re based in the Barrie area and have been designing and building outdoor structures throughout Simcoe County for over 40 years. We know:

- Local building codes and what inspectors expect

- Soil conditions and foundation requirements

- Wind and snow loads for the region

- Material suppliers and quality products

- Reputable contractors (if you need referrals)

- Realistic pricing for our market

This local expertise matters. A designer from another region might create beautiful renderings, but will they understand Springwater Township’s specific code requirements? Do they know which materials perform well in our climate? Have they built relationships with local building departments?

Our Local Service Area Includes:

- Barrie

- Springwater Township (including Midhurst, Minesing, Elmvale)

- Tiny Township

- Innisfil

- Oro-Medonte

- Orillia

- Wasaga Beach

- Collingwood

- The Blue Mountains

- Clearview Township

- Bradford West Gwillimbury

We also provide design services (without construction) throughout Ontario and across North America.

Beyond Decks: Complete Outdoor Living Design

While this project focused on deck design, we provide comprehensive outdoor living design services:

Outdoor Structures We Design:

- Custom decks (accessible, multi-level, rooftop)

- Pergolas and pavilions

- Pool cabanas and pool houses

- Outdoor kitchens and bars

- Privacy screens and wind walls

- Covered outdoor living rooms

- Screened porches and three-season rooms

- Deck enclosures and sunrooms

Related Design Services:

- Landscape lighting design

- Drainage and grading solutions

- Hardscape integration (patios, walkways)

- Masonry repair and rebuilding

- Foundation engineering (helical piles, concrete piers)

- Accessibility modifications

- Code compliance consulting

What Sets Us Apart: Designers Who Actually Build

Here’s the fundamental difference between us and typical architectural firms:

We started as builders. We’ve spent 40 years with tools in our hands, solving real problems on actual job sites. We didn’t learn construction from textbooks – we learned it by doing it, day after day, year after year.

This means:

We Design for Buildability

Every detail in our drawings can actually be constructed. We don’t draw impossible connections or specify materials that don’t exist. If it’s in our plans, it can be built.

We Understand Real Costs

We know what things actually cost because we’ve bought the materials and paid the labor. We can design to your budget because we understand the numbers intimately.

We Solve Problems in Real Time

When we discovered those tractor parts in the Midhurst concrete slab, we didn’t panic or punt the problem to someone else. We adapted the design intelligently because we’ve dealt with thousands of surprises over four decades.

We Respect Contractors

We create drawings that make contractors’ jobs easier, not harder. We provide details they can actually use. We answer questions quickly. We understand their challenges because we’ve been there.

We Stand Behind Our Designs

When that ice storm branch hit the deck and caused zero damage, we felt vindicated but not surprised. We engineered it to withstand exactly that kind of abuse. That’s what proper design and quality construction deliver.

Group Home and Institutional Design Experience

The Midhurst project highlights our experience with specialized facilities:

Understanding Unique Requirements

Group homes, assisted living facilities, and institutional settings have requirements beyond typical residential projects:

- Enhanced accessibility beyond basic code compliance

- Durability for high-traffic, high-use conditions

- Safety features appropriate to resident needs

- Materials that tolerate intensive use

- Maintenance considerations for staff efficiency

- Dignity and comfort for residents

Working Within Institutional Budgets

Facilities like group homes operate on tight budgets. We excel at maximizing value:

- Engineering for extreme longevity (reducing replacement costs)

- Specifying maintainable materials (reducing ongoing costs)

- Designing for multiple users (maximizing utility)

- Building once, building right (avoiding do-overs)

Long-Term Partnerships

“A Helping Hand Always” keeps coming back because we understand their mission and deliver designs that support it. This is the kind of relationship we build with all our institutional clients.

Ice Storm Validation: When Engineering Matters

Let’s return to that ice storm one more time, because it perfectly illustrates why engineering and quality construction matter.

A large branch fell directly onto this deck during the storm. This wasn’t a small twig – this was a substantial limb carrying ice weight.

The deck suffered zero damage.

This happened because:

We Engineered for Real Loads: Our structural calculations accounted for extraordinary snow and impact loads, not just code minimums.

We Built Heavy: Those 3-ply beams and 2×10 joists at 12″ on center provided massive strength reserves.

We Used Quality Connections: Proper hardware and fasteners held everything together under impact.

We Specified Durable Materials: The Azek decking, glass railings, and Douglas fir pergola all shrugged off the impact.

We Built It Right: Proper construction techniques meant everything performed as designed.

When Mother Nature stress-tests your work and it passes with flying colors, that’s the ultimate validation of design decisions made years earlier.

Ready to Design Your Barrie Area Deck?

Whether you’re planning a simple backyard deck or a complex accessible structure like our Midhurst project, we bring four decades of design-build expertise to every project.

What You Get When Working With Us:

- Comprehensive 3D photorealistic rendering

- Complete construction documentation

- Building permit support

- Local expertise (Barrie and Simcoe County)

- Realistic cost guidance

- Designs that actually get built successfully

- Long-term durability (30+ year performance)

- Designers who understand construction intimately

Get Started Today:

Phone: +1 416-951-9998

Email: LW@designyourreno.com

Website: DesignYourReno.com

We provide design services throughout Ontario and across North America. For design-build services, we focus on Barrie, Springwater, and the surrounding Simcoe County region.

Get in touch to have your dream deck design created soon!

Frequently Asked Questions: 3D Deck Design in Barrie

How much does professional 3D deck design cost?

Design fees vary based on project complexity. Simple deck layouts start around $1,500-$2,000 for concept renderings and basic plans. Complex projects like the Midhurst group home requiring structural engineering, multiple design iterations, lighting design, and complete construction documents typically range from $3,000-$5,000+. This investment saves far more during construction by preventing changes, clarifying contractor pricing, and ensuring building permit approval.

How long does the deck design process take?

Most deck design projects take 2-4 weeks from initial consultation to complete construction documents. Complex projects requiring structural engineering or significant site work may take 4-8 weeks. Once you approve the design, we can typically have permit-ready drawings within days.

Do I need a building permit for my Barrie-area deck?

Almost certainly yes. Most municipalities in Simcoe County (including Barrie, Springwater, Tiny Township, and Innisfil) require building permits for:

- Decks over 24 inches above grade

- Decks attached to the house

- Decks with any roof covering

- Decks with electrical or plumbing

We create permit-ready drawings and support you through the approval process.

What makes your 3D deck renderings different from other companies?

Many deck designers use basic software that creates generic visualizations. We create photorealistic architectural renderings that show:

- Actual material textures and finishes

- Accurate lighting conditions (day and night views)

- Integration with your specific house

- Multiple viewing angles

- Real-world context

Our renderings are construction documents, not just sales tools. Contractors can build from them. Building departments can approve from them. You can see exactly what you’re getting.

Can you design decks for existing problematic structures?

Absolutely. The Midhurst project is a perfect example – we dealt with failing masonry, compromised concrete, below-grade windows, and tree damage all in one project. We excel at solving complex structural problems and integrating new construction with challenging existing conditions.

Do you only design decks, or do you also build them?

We do both. For clients in the Barrie and Simcoe County region, we offer complete design-build services. For clients elsewhere in Ontario or across North America, we provide design services and construction documents that any qualified contractor can build from.

What’s the advantage of helical pile foundations?

Traditional concrete piers can heave with frost, settle over time, and deteriorate in our freeze-thaw climate. Helical piles:

- Provide 100-year foundation performance

- Never heave or settle

- Can be installed year-round

- Support higher loads

- Transfer load to stable soil deep underground

- Remain perfectly level permanently

For decks you want to last generations, helical piles are the right foundation.

How do you design for accessibility?

We have extensive experience designing accessible outdoor spaces including:

- ADA-compliant ramps and transitions

- Wide pathways for wheelchair maneuvering

- Appropriate railing heights and configurations

- Smooth surface transitions

- Adequate turning radiuses

- Universal design principles

The Midhurst group home project showcases our accessibility expertise.

Can you help if I’ve already had a deck designed but need modifications?

Yes. We frequently refine existing deck designs to:

- Improve functionality

- Resolve building code issues

- Reduce costs while maintaining quality

- Add accessibility features

- Integrate with changed site conditions

- Create proper construction details

What areas do you serve?

Design services: Available throughout Ontario and across North America (remote design process)

Design + Build services: Barrie, Springwater, Tiny Township, Innisfil, Oro-Medonte, Orillia, Wasaga Beach, Collingwood, The Blue Mountains, Clearview Township, and surrounding Simcoe County areas

Do you design other outdoor structures besides decks?

Yes! We design complete outdoor living spaces including:

- Pergolas and pavilions

- Pool cabanas and pool houses

- Outdoor kitchens

- Privacy screens and wind walls

- Screened porches

- Deck enclosures

- Landscape lighting

Professional 3D deck design in Barrie, Springwater, and Simcoe County. Forty years of design-build expertise. Designs that last generations.

Contact us today to discuss your project: +1 416-951-9998 | LW@designyourreno.com